Understanding the Difference Between OPRP and CCP in Food Safety

Understanding the Difference Between OPRP and CCP in Food Safety

Food safety is a top priority in the food industry, ensuring that consumers receive safe and high-quality products. Two critical concepts in food safety management systems, particularly in HACCP (Hazard Analysis and Critical Control Points), are CCP (Critical Control Point) and OPRP (Operational Prerequisite Program). Understanding the difference between these two terms is essential for maintaining food safety standards and compliance with global regulations.

What is a Critical Control Point (CCP)?

A Critical Control Point (CCP) is a specific step in the food production process where control measures are applied to prevent, eliminate, or reduce a food safety hazard to an acceptable level. If a CCP fails, the food may become unsafe for consumption.

Examples of CCPs:

Cooking Temperature Control: Ensuring that chicken is cooked to 75°C to eliminate harmful bacteria.

Pasteurization: Heating milk at a specific temperature for a defined time to kill pathogens.

Metal Detection: Using metal detectors to prevent physical hazards from entering the final product.

pH and Water Activity Control: Monitoring acidity and moisture levels in processed foods to prevent microbial growth.

What is an Operational Prerequisite Program (OPRP)?

An Operational Prerequisite Program (OPRP) is a preventive control measure implemented to reduce the likelihood of a food safety hazard but is not as critical as a CCP. OPRPs help ensure the effectiveness of the overall food safety system and support the control measures at CCPs.

Examples of OPRPs:

Handwashing and Hygiene Practices: Ensuring food handlers wash hands properly before touching food.

Cleaning and Sanitation: Regular cleaning of equipment and surfaces to prevent cross-contamination.

Pest Control Programs: Preventing infestations that could compromise food safety.

Allergen Control Measures: Managing potential cross-contact of allergens in food production.

Key Differences Between CCP and OPRP

| Feature | Critical Control Point (CCP) | Operational Prerequisite Program (OPRP) |

|---|---|---|

| Purpose | Eliminates or reduces hazards to safe levels | Prevents hazards from occurring but does not eliminate them |

| Control Level | High-level control of significant hazards | Supports overall food safety but is not a final safety step |

| Examples | Cooking, pasteurization, metal detection | Handwashing, sanitation, pest control |

| Monitoring | Continuous and documented | Periodic checks and standard operating procedures |

| Corrective Action | If CCP fails, immediate action is needed | OPRP failure may require improvements in procedures |

Why Understanding CCP and OPRP Matters in HACCP Implementation?

Implementing CCP and OPRP correctly is vital for maintaining food safety and ensuring compliance with HACCP, ISO 22000, and other global food safety standards. Misidentifying a CCP as an OPRP or vice versa can lead to food safety risks and regulatory non-compliance.

Best Practices for Identifying CCPs and OPRPs:

Conduct a Hazard Analysis: Identify potential biological, chemical, and physical hazards.

Use a Decision Tree: Determine whether a control measure should be classified as a CCP or OPRP.

Ensure Proper Monitoring: Establish monitoring procedures for both CCPs and OPRPs.

Document Everything: Maintain records of all food safety measures and corrective actions.

Train Your Staff: Educate employees on the importance of CCPs and OPRPs in maintaining food safety.

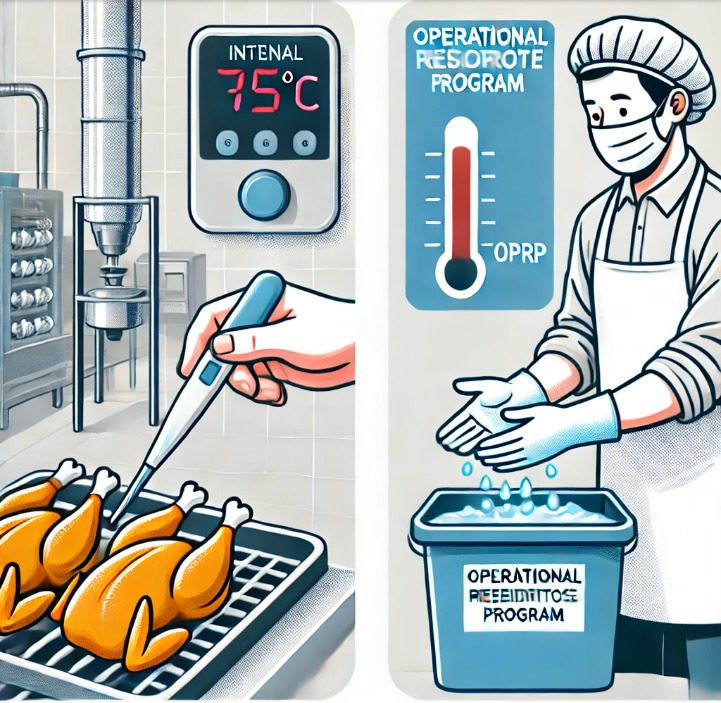

Visual Representation of CCP and OPRP

CCP Example:

A food factory worker using a thermometer to check the internal temperature of cooked chicken to ensure it reaches 75°C, preventing bacterial contamination.

OPRP Example:

A food factory worker washing hands at a designated hygiene station before handling food, reducing the risk of contamination but not directly eliminating hazards.

Final Thoughts

Both CCP and OPRP play crucial roles in ensuring food safety. CCPs focus on eliminating or reducing hazards, while OPRPs work to prevent contamination through good manufacturing practices. Understanding and correctly implementing these measures can help food businesses maintain high safety standards, pass audits, and ensure consumer trust.

By effectively managing CCPs and OPRPs, food businesses can minimize risks, comply with food safety laws, and protect public health.

Have Questions About Food Safety?

Let us know in the comments, or reach out for expert food safety consultation services!